Outline three methods an organization could use to gain feedback from stakeholders (25 points)

See the answer in Explanation below:

Gaining feedback from stakeholders helps organizations understand their needs and improve performance. Below are three methods, detailed step-by-step:

Surveys and Questionnaires

Step 1: Design the ToolCreate structured questions (e.g., Likert scales, open-ended) tailored to stakeholder groups like customers or suppliers.

Step 2: DistributionDistribute via email, online platforms, or in-person to ensure accessibility.

Step 3: AnalysisCollect and analyze responses to identify trends or issues (e.g., supplier satisfaction with payment terms).

Outcome:Provides quantitative and qualitative insights efficiently.

Focus Groups

Step 1: Organize the SessionInvite a small, diverse group of stakeholders (e.g., employees, clients) for a facilitated discussion.

Step 2: Conduct the DiscussionUse open-ended questions to explore perceptions (e.g., “How can we improve delivery times?”).

Step 3: Record and InterpretSummarize findings to capture detailed, nuanced feedback.

Outcome:Offers in-depth understanding of stakeholder views.

One-on-One Interviews

Step 1: Select ParticipantsChoose key stakeholders (e.g., major suppliers, senior staff) for personalized engagement.

Step 2: Conduct InterviewsAsk targeted questions in a private setting to encourage candid responses.

Step 3: Synthesize FeedbackCompile insights to address specific concerns or opportunities.

Outcome:Builds trust and gathers detailed, individual perspectives.

Exact Extract Explanation:

The CIPS L5M4 Study Guide highlights stakeholder feedback methods:

Surveys:"Surveys provide a scalable way to gather structured feedback from diverse stakeholders" (CIPS L5M4 Study Guide, Chapter 1, Section 1.8).

Focus Groups:"Focus groups enable qualitative exploration of stakeholder opinions" (CIPS L5M4 Study Guide, Chapter 1, Section 1.8).

Interviews:"One-on-one interviews offer detailed, personal insights, fostering stronger relationships" (CIPS L5M4 Study Guide, Chapter 1, Section 1.8).These methods enhance stakeholder engagement in procurement and financial decisions. References: CIPS L5M4 Study Guide, Chapter 1: Organizational Objectives and Financial Management.

Explain what is meant by a ‘commodity’ (8 points) and why prices of commodities can be characterized as ‘volatile’ (17 points)

See the answer in Explanation below:

Part 1: Definition of a Commodity (8 points)

Step 1: Define the TermA commodity is a raw material or primary product traded in bulk, typically uniform in quality across producers (e.g., oil, wheat, copper).

Step 2: Characteristics

Standardized and interchangeable (fungible).

Traded on global markets or exchanges.

Used as inputs in production or consumption.

Outcome:Commodities are basic goods with little differentiation, driving their market-based pricing.

Part 2: Why Commodity Prices Are Volatile (17 points)

Step 1: Supply and Demand FluctuationsPrices swing due to unpredictable supply (e.g., weather affecting crops) or demand shifts (e.g., industrial slowdowns).

Step 2: Geopolitical EventsConflicts or sanctions (e.g., oil embargoes) disrupt supply, causing price spikes or drops.

Step 3: Currency MovementsMost commodities are priced in USD; a stronger USD raises costs for non-US buyers, reducing demand and affecting prices.

Step 4: Speculative TradingInvestors betting on future price movements amplify volatility beyond physical supply/demand.

Outcome:These factors create rapid, unpredictable price changes, defining commodity volatility.

Exact Extract Explanation:

Commodity Definition:The CIPS L5M4 Study Guide states, "Commodities are standardized raw materials traded globally, valued for their uniformity and utility" (CIPS L5M4 Study Guide, Chapter 6, Section 6.1).

Price Volatility:It explains, "Commodity prices are volatile due to supply disruptions, demand variability, geopolitical risks, currency fluctuations, and speculative activity" (CIPS L5M4 Study Guide, Chapter 6, Section 6.2). Examples include oil price shocks from OPEC decisions or agricultural losses from droughts.This understanding is key for procurement strategies in volatile markets. References: CIPS L5M4 Study Guide, Chapter 6: Commodity Markets and Procurement.===========

Explain what is meant by ‘supplier selection’ (25 marks)

See the answer in Explanation below:

Supplier selection is a critical process in procurement and contract management, involving the evaluation and choice of suppliers to meet an organization’s needs for goods, services, or materials. In the context of the CIPS L5M4 Advanced Contract and Financial Management study guide, supplier selection is a strategic activity that ensures suppliers align with financial, operational, and strategic objectives, delivering value for money and minimizing risks. Below is a detailed explanation, broken down step-by-step:

Definition:

Supplier selection is the process of identifying, evaluating, and choosing suppliers based on predefined criteria to fulfill an organization’s procurement requirements.

It involves assessing potential suppliers’ capabilities, performance, and alignment with the buyer’s goals.

Purpose:

Ensures the selected supplier can deliver the right quality, quantity, and timing of goods or services while meeting financial and contractual expectations.

Aims to minimize risks (e.g., supply disruptions) and maximize value (e.g., cost efficiency, innovation).

Example: XYZ Ltd (Question 7) selects a raw material supplier based on cost, quality, and reliability.

Key Steps in Supplier Selection:

Identify Needs: Define the organization’s requirements (e.g., specific raw materials, delivery schedules).

Develop Criteria: Establish evaluation criteria (e.g., cost, quality, financial stability—see Questions 7 and 13).

Source Potential Suppliers: Use competitive (Question 16) or non-competitive sourcing to create a shortlist.

Evaluate Suppliers: Assess candidates against criteria using tools like scorecards or financial analysis.

Negotiate and Select: Choose the best supplier and negotiate contract terms.

Example: Rachel (Question 17) might shortlist suppliers for raw materials, evaluate them on price and delivery, and select the one offering the best overall value.

Importance in Contract Management:

Supplier selection directly impacts contract performance—choosing the wrong supplier can lead to delays, quality issues, or cost overruns.

It aligns with financial management by ensuring cost efficiency and risk mitigation, key L5M4 principles.

Example: Selecting a financially stable supplier (Question 13) reduces the risk of mid-contract failure.

Strategic Considerations:

Involves balancing short-term needs (e.g., immediate cost savings) with long-term goals (e.g., supplier innovation—Question 2).

May incorporate strategic sourcing principles (Question 11) to align with organizational objectives like sustainability or innovation.

Example: A company might select a supplier with strong innovation capacity to support future product development.

Exact Extract Explanation:

The CIPS L5M4 Advanced Contract and Financial Management study guide defines supplier selection as "the process of evaluating and choosing suppliers to meet organizational needs while ensuring value for money and minimizing risks." It is a foundational element of procurement, discussed extensively in the context of performance management, risk mitigation, and financial efficiency. The guide emphasizes that supplier selection is not just about cost but involves a "structured evaluation" to ensure suppliers deliver on quality, reliability, and strategic objectives.

Detailed Explanation:

The guide outlines supplier selection as a multi-step process, starting with "defining requirements" and ending with "contract award." This structured approach ensures fairness and alignment with organizational goals.

Chapter 2 stresses that supplier selection should use "robust criteria" (e.g., cost, quality, financial stability—Question 7) to evaluate candidates, often through tools like weighted scorecards or financial analysis (Question 13).

The guide links supplier selection to financial management by noting its role in "cost control" and "risk reduction." For instance, selecting a supplier with a strong Current Ratio (Question 13) ensures they can meet short-term obligations, avoiding supply disruptions that could inflate costs.

It also highlights the strategic aspect, integrating concepts like innovation capacity (Question 2) and industry analysis (Question 14) to select suppliers who support long-term goals, such as sustainability or technological advancement.

Practical Application:

For Rachel (Question 17), supplier selection for raw materials involves defining needs (e.g., consistent steel supply), setting criteria (e.g., price, quality, delivery), shortlisting suppliers, evaluating them (e.g., via financial data), and choosing the best fit. This ensures her manufacturing operations run smoothly and cost-effectively.

The guide advises involving cross-functional teams (e.g., procurement, production, finance) to ensure criteria reflect organizational priorities, enhancing the selection process’s effectiveness.

Broader Implications:

Supplier selection impacts the entire contract lifecycle—poor selection can lead to performance issues, requiring corrective actions like supplier development (Question 3).

Financially, it ensures value for money by selecting suppliers who offer the best balance of cost, quality, and reliability, aligning with L5M4’s core focus.

The guide also notes that selection should be revisited periodically, as market conditions (Question 14) or supplier performance may change, requiring adjustments to maintain contract success.

Discuss the different financial objectives of the following organization types: public sector, private sector, charity sector (25 points)

See the answer in Explanation below:

The financial objectives of organizations vary significantly depending on their type—public sector, private sector, or charity sector. Below is a detailed step-by-step explanation of the financial objectives for each:

Public Sector Organizations

Step 1: Understand the PurposePublic sector organizations are government-owned or controlled entities focused on delivering public services rather than generating profit.

Step 2: Identify Financial Objectives

Value for Money (VfM):Ensuring efficient use of taxpayer funds by balancing economy, efficiency, and effectiveness.

Budget Compliance:Operating within allocated budgets set by government policies.

Service Delivery:Prioritizing funds to meet public needs (e.g., healthcare, education) rather than profit.

Cost Control:Minimizing waste and ensuring transparency in financial management.

Private Sector Organizations

Step 1: Understand the PurposePrivate sector organizations are privately owned businesses aiming to generate profit for owners or shareholders.

Step 2: Identify Financial Objectives

Profit Maximization:Achieving the highest possible financial returns.

Shareholder Value:Increasing share prices or dividends for investors.

Revenue Growth:Expanding sales and market share to boost income.

Cost Efficiency:Reducing operational costs to improve profit margins.

Charity Sector Organizations

Step 1: Understand the PurposeCharities are non-profit entities focused on social, environmental, or humanitarian goals rather than profit.

Step 2: Identify Financial Objectives

Fundraising Efficiency:Maximizing income from donations, grants, or events.

Cost Management:Keeping administrative costs low to direct funds to the cause.

Sustainability:Ensuring long-term financial stability to continue operations.

Transparency:Demonstrating accountability to donors and stakeholders.

Exact Extract Explanation:

The CIPS L5M4 Advanced Contract and Financial Management study guide emphasizes understanding organizational objectives as a foundation for effective financial and contract management. According to the guide:

Public Sector:The focus is on "delivering value for money and achieving social outcomes rather than profit" (CIPS L5M4 Study Guide, Chapter 1, Section 1.2). This includesadhering to strict budgetary controls and public accountability standards.

Private Sector:The guide highlights that "private sector organizations prioritize profit maximization and shareholder wealth" (CIPS L5M4 Study Guide, Chapter 1, Section 1.3). Financial strategies are aligned with competitive market performance and cost efficiencies.

Charity Sector:Charities aim to "maximize the impact of funds raised while maintaining financial sustainability" (CIPS L5M4 Study Guide, Chapter 1, Section 1.4). This involves balancing fundraising efforts with low overheads and compliance with regulatory requirements.These distinctions are critical for procurement professionals to align contract strategies with organizational goals. References: CIPS L5M4 Study Guide, Chapter 1: Organizational Objectives and Financial Management.

Describe what is meant by ‘Supply Chain Integration’ (8 marks). How would a buyer go about implementing this approach and what benefits could be gained from it? (17 marks).

See the answer in Explanation below:

Part 1: Describe what is meant by ‘Supply Chain Integration’ (8 marks)

Supply Chain Integration (SCI) refers to the seamless coordination and alignment of processes, information, and resources across all parties in a supply chain—suppliers, manufacturers, distributors, and buyers—to achieve a unified, efficient system. In the context of the CIPS L5M4 Advanced Contract and Financial Management study guide, SCI emphasizes collaboration to optimize performance and deliver value. Below is a step-by-step explanation:

Definition:

SCI involves linking supply chain partners to work as a cohesive unit, sharing goals, data, and strategies.

It spans upstream (suppliers) and downstream (customers) activities.

Purpose:

Aims to eliminate silos, reduce inefficiencies, and enhance responsiveness to market demands.

Example: A buyer and supplier share real-time inventory data to prevent stockouts.

Part 2: How would a buyer go about implementing this approach and what benefits could be gained from it? (17 marks)

Implementation Steps:

Establish Collaborative Relationships:

Build trust and partnerships with suppliers through regular communication and joint planning.

Example: Set up quarterly strategy meetings with key suppliers.

Implement Information Sharing Systems:

Use technology (e.g., ERP systems, cloud platforms) to share real-time data on demand, inventory, and forecasts.

Example: Integrate a supplier’s system with the buyer’s to track orders live.

Align Objectives and KPIs:

Agree on shared goals and performance metrics (e.g., delivery speed, cost reduction) to ensure mutual accountability.

Example: Both parties target a 95% on-time delivery rate.

Streamline Processes:

Redesign workflows (e.g., joint procurement or production planning) to eliminate redundancies.

Example: Co-develop a just-in-time delivery schedule.

Benefits:

Improved Efficiency:

Streamlined operations reduce waste and lead times.

Example: Cutting order processing time from 5 days to 2 days.

Cost Savings:

Better coordination lowers inventory holding costs and optimizes resource use.

Example: Reducing excess stock by 20% through shared forecasting.

Enhanced Responsiveness:

Real-time data enables quick adaptation to demand changes.

Example: Adjusting supply within 24 hours of a sales spike.

Stronger Relationships:

Collaboration fosters trust and long-term supplier commitment.

Example: A supplier prioritizes the buyer during shortages.

Exact Extract Explanation:

Part 1: What is Supply Chain Integration?

The CIPS L5M4 Advanced Contract and Financial Management study guide does not dedicate a specific section to SCI but embeds it within discussions on supplier relationships and performance optimization. It describes SCI as "the alignment of supply chain activities to achieve a seamless flow of goods, services, and information." The guide positions it as a strategic approach to enhance contract outcomes by breaking down barriers between supply chain partners, aligning with its focus on value delivery and financial efficiency.

Detailed Explanation:

SCI integrates processes like procurement, production, and logistics across organizations. The guide notes that "effective supply chains require coordination beyond contractual obligations," emphasizing shared goals over transactional interactions.

For example, a manufacturer (buyer) integrating with a raw material supplier ensures materials arrive just as production ramps up, avoiding delays or overstocking. This reflects L5M4’s emphasis on operational and financial synergy.

Part 2: Implementation and Benefits

The study guide highlights SCI as a means to "maximize efficiency and value," linking it to contract management and financial performance. It provides implicit guidance on implementation and benefits through its focus on collaboration and performance metrics.

Implementation Steps:

Establish Collaborative Relationships:

Chapter 2 stresses "partnership approaches" to improve supplier performance. This starts with trust-building activities like joint workshops, aligning with SCI’s collaborative ethos.

Implement Information Sharing Systems:

The guide advocates "technology-enabled transparency" (e.g., shared IT platforms) to enhance visibility, a cornerstone of SCI. This reduces guesswork and aligns supply with demand.

Align Objectives and KPIs:

L5M4 emphasizes "mutually agreed performance measures" (e.g., KPIs like delivery accuracy). SCI requires this alignment to ensure all parties work toward common outcomes.

Streamline Processes:

The guide suggests "process optimization" through collaboration, such assynchronized planning, to eliminate inefficiencies—a practical step in SCI.

Benefits:

Improved Efficiency:

The guide links integrated processes to "reduced cycle times," a direct outcome of SCI. For instance, shared data cuts delays, aligning with operational goals.

Cost Savings:

Chapter 4 highlights "minimizing waste" as a financial management priority. SCI reduces excess inventory and transport costs, delivering tangible savings.

Enhanced Responsiveness:

The guide notes that "agile supply chains adapt to market shifts," a benefit of SCI’s real-time coordination. This supports competitiveness, a strategic L5M4 focus.

Stronger Relationships:

Collaboration "builds resilience and trust," per the guide. SCI fosters partnerships, ensuring suppliers prioritize the buyer’s needs, enhancing contract stability.

Practical Application:

For XYZ Ltd (from Question 7), SCI might involve integrating a raw material supplier into their production planning. Implementation includes an ERP link for inventory data, aligned KPIs (e.g., 98% delivery reliability), and joint scheduling. Benefits could include a 15% cost reduction, 3-day faster lead times, and a supplier committed to priority service during peak demand.

The guide advises balancing integration costs (e.g., IT investment) with long-term gains, a key financial consideration in L5M4.

A company is keen to assess the innovation capacity of a supplier. Describe what is meant by 'innovation capacity' and explain what measures could be used. (25 marks)

See the answer in Explanation below:

Innovation capacity refers to a supplier’s ability to develop, implement, and sustain new ideas, processes, products, or services that add value to their offerings and enhance the buyer’s operations. In the context of the CIPS L5M4 Advanced Contract and Financial Management study guide, assessing a supplier’s innovation capacity is crucial for ensuring long-term value, maintaining competitive advantage, and achieving cost efficiencies or performance improvements through creative solutions. Below is a detailed step-by-step solution:

Definition of Innovation Capacity:

It is the supplier’s capability to generate innovative outcomes, such as improved products, efficient processes, or novel business models.

It encompasses creativity, technical expertise, resource availability, and a culture that supports innovation.

Why It Matters:

Innovation capacity ensures suppliers can adapt to changing market demands, technological advancements, or buyer needs.

It contributes to financial management by reducing costs (e.g., through process improvements) or enhancing quality, aligning with the L5M4 focus on value for money.

Measures to Assess Innovation Capacity:

Research and Development (R&D) Investment: Percentage of revenue spent on R&D (e.g., 5% of annual turnover).

Number of Patents or New Products: Count of patents filed or new products launched in a given period (e.g., 3 new patents annually).

Process Improvement Metrics: Reduction in production time or costs due to innovative methods (e.g., 15% faster delivery).

Collaboration Initiatives: Frequency and success of joint innovation projects with buyers (e.g., 2 successful co-developed solutions).

Employee Innovation Programs: Existence of schemes like suggestion boxes or innovation awards (e.g., 10 staff ideas implemented yearly).

Exact Extract Explanation:

The CIPS L5M4 Advanced Contract and Financial Management study guide emphasizes the importance of supplier innovation as a driver of contractual success and financial efficiency. While the guide does not explicitly define "innovation capacity," it aligns the concept with supplier performance management and the ability to deliver "value beyond cost savings." Innovation capacity is framed as a strategic attribute that enhances competitiveness and ensures suppliers contribute to the buyer’s long-term goals.

Detailed Definition:

Innovation capacity involves both tangible outputs (e.g., new technology) and intangible strengths (e.g., a proactive mindset). The guide suggests that suppliers with high innovation capacity can "anticipate and respond to future needs," which iscritical in dynamic industries like technology or manufacturing.

It is linked to financial management because innovative suppliers can reduce total cost of ownership (e.g., through energy-efficient products) or improve return on investment (ROI) by offering cutting-edge solutions.

Why Assess Innovation Capacity:

Chapter 2 of the study guide highlights that supplier performance extends beyond meeting basic KPIs to delivering "strategic benefits." Innovation capacity ensures suppliers remain relevant and adaptable, reducing risks like obsolescence.

For example, a supplier innovating in sustainable packaging could lower costs and meet regulatory requirements, aligning with the L5M4 focus on financial and operational sustainability.

Measures Explained:

R&D Investment:

The guide notes that "investment in future capabilities" is a sign of a forward-thinking supplier. Measuring R&D spend (e.g., as a percentage of revenue) indicates commitment to innovation. A supplier spending 5% of its turnover on R&D might develop advanced materials, benefiting the buyer’s product line.

Patents and New Products:

Tangible outputs like patents demonstrate a supplier’s ability to innovate. The guide suggests tracking "evidence of innovation" to assess capability. For instance, a supplier launching 2 new products yearly shows practical application of creativity.

Process Improvements:

Innovation in processes (e.g., lean manufacturing) can reduce costs or lead times. The guide links this to "efficiency gains," a key financial management goal. A 10% reduction in production costs due to a new technique is a measurable outcome.

Collaboration Initiatives:

The study guide encourages "partnership approaches" in contracts. Joint innovation projects (e.g., co-developing a software tool) reflect a supplier’s willingness to align with buyer goals. Success could be measured by project completion or ROI.

Employee Innovation Programs:

A culture of innovation is vital, as per the guide’s emphasis on supplier capability. Programs encouraging staff ideas (e.g., 20 suggestions implemented annually) indicate a grassroots-level commitment to creativity.

Practical Application:

To assess these measures, a company might use a supplier evaluation scorecard, assigning weights to each metric (e.g., 30% for R&D, 20% for patents). The guide advises integrating such assessments into contract reviews to ensure ongoing innovation.

For instance, a supplier with a high defect rate but strong R&D investment might be retained if their innovation promises future quality improvements. This aligns with L5M4’s focus on balancing short-term performance with long-term potential.

Broader Implications:

Innovation capacity can be a contractual requirement, with KPIs like "number of innovative proposals submitted" (e.g., 4 per year) formalizing expectations.

The guide also warns against over-reliance on past performance, advocating for forward-looking measures like those above to predict future value.

Financially, innovative suppliers might command higher initial costs but deliver greater savings or market advantages over time, a key L5M4 principle.

A manufacturing organization is looking into the option of benchmarking. Describe how a benchmarking exercise can be conducted and common reasons for benchmarking failure that the organization should be aware of (25 points)

See the answer in Explanation below:

Part 1: How a Benchmarking Exercise Can Be ConductedA benchmarking exercise follows a structured process to ensure meaningful outcomes:

Step 1: Define ObjectivesIdentify goals (e.g., reduce production costs, improve lead times) and select metrics (e.g., cost per unit).

Step 2: Choose Benchmarking TypeDecide on internal (e.g., between plants), competitive (e.g., rival firm), or best-in-class (e.g., industry leader).

Step 3: Collect DataGather internal performance data and external benchmarks via research, surveys, or industry reports.

Step 4: Analyze GapsCompare data to identify disparities (e.g., higher costs than peers) and root causes.

Step 5: Implement ImprovementsDevelop and execute an action plan based on findings (e.g., adopt new technology).

Step 6: Monitor ResultsTrack progress and adjust strategies to sustain gains.

Outcome:Systematically improves manufacturing performance.

Part 2: Common Reasons for Benchmarking Failure

Step 1: Lack of Clear ObjectivesVague goals (e.g., “improve efficiency”) lead to unfocused efforts and poor results.

Step 2: Poor Data QualityInaccurate or incomplete data (e.g., outdated competitor stats) skews comparisons.

Step 3: Resistance to ChangeStaff or management reluctance to adopt new practices stalls implementation.

Outcome:Undermines the exercise’s effectiveness.

Exact Extract Explanation:

The CIPS L5M4 Study Guide outlines benchmarking processes and pitfalls:

Process:"Benchmarking involves setting objectives, selecting comparators, collecting and analyzing data, implementing changes, and monitoring outcomes" (CIPS L5M4 Study Guide, Chapter 2, Section 2.6).

Failures:"Common failures include unclear objectives, unreliable data, and organizational resistance" (CIPS L5M4 Study Guide, Chapter 2, Section 2.6).This is critical for manufacturing firms optimizing supply chains. References: CIPS L5M4 Study Guide, Chapter 2: Supply Chain Performance Management.

ABC Ltd wishes to implement a new communication plan with various stakeholders. How could ABC go about doing this? (25 points)

See the answer in Explanation below:

To implement a new communication plan with stakeholders, ABC Ltd can follow a structured approach to ensure clarity, engagement, and effectiveness. Below is a step-by-step process:

Identify Stakeholders and Their Needs

Step 1: Stakeholder MappingUse tools like the Power-Interest Matrix to categorize stakeholders (e.g., employees, suppliers, customers) based on influence and interest.

Step 2: Assess NeedsDetermine communication preferences (e.g., suppliers may need contract updates, employees may want operational news).

Outcome:Tailors the plan to specific stakeholder requirements.

Define Objectives and Key Messages

Step 1: Set GoalsEstablish clear aims (e.g., improve supplier collaboration, enhance customer trust).

Step 2: Craft MessagesDevelop concise, relevant messages aligned with objectives (e.g., “We’re streamlining procurement for faster delivery”).

Outcome:Ensures consistent, purpose-driven communication.

Select Communication Channels

Step 1: Match Channels to StakeholdersChoose appropriate methods: emails for formal updates, meetings for key partners, social media for customers.

Step 2: Ensure AccessibilityUse multiple platforms (e.g., newsletters, webinars) to reach diverse groups.

Outcome:Maximizes reach and engagement.

Implement and Monitor the Plan

Step 1: Roll OutLaunch the plan with a timeline (e.g., weekly supplier briefings, monthly staff updates).

Step 2: Gather FeedbackUse surveys or discussions to assess effectiveness and adjust as needed.

Outcome:Ensures the plan remains relevant and impactful.

Exact Extract Explanation:

The CIPS L5M4 Study Guide emphasizes structured communication planning:

"Effective communication requires identifying stakeholders, setting clear objectives, selecting appropriate channels, and monitoring outcomes" (CIPS L5M4 Study Guide, Chapter 1, Section 1.8). It stresses tailoring approaches to stakeholder needs and using feedback for refinement, critical for procurement and contract management. References: CIPS L5M4 Study Guide, Chapter 1: Organizational Objectives and Financial Management.===========

What is meant by the term benchmarking? (10 points) Describe two forms of benchmarking (15 points)

See the answer in Explanation below:

Part 1: Meaning of Benchmarking (10 points)

Step 1: Define the TermBenchmarking is the process of comparing an organization’s processes, performance, or practices against a standard or best-in-class example to identify improvement opportunities.

Step 2: PurposeAims to enhance efficiency, quality, or competitiveness by learning from others.

Step 3: ApplicationInvolves measuring metrics (e.g., cost per unit, delivery time) against peers or industry leaders.

Outcome:Drives continuous improvement through comparison.

Part 2: Two Forms of Benchmarking (15 points)

Internal Benchmarking

Step 1: Define the FormCompares performance between different units, teams, or processes within the same organization.

Step 2: ExampleABC Ltd compares delivery times between its UK and US warehouses to share best practices.

Step 3: BenefitsEasy access to data, fosters internal collaboration, and leverages existing resources.

Outcome:Improves consistency and efficiency internally.

Competitive Benchmarking

Step 1: Define the FormCompares performance directly with a competitor in the same industry.

Step 2: ExampleABC Ltd assesses its production costs against a rival manufacturer to identify cost-saving opportunities.

Step 3: BenefitsHighlights competitive gaps and drives market positioning improvements.

Outcome:Enhances external competitiveness.

Exact Extract Explanation:

Definition:The CIPS L5M4 Study Guide states, "Benchmarking involves comparing organizational performance against a reference point to identify areas for enhancement" (CIPS L5M4 Study Guide, Chapter 2, Section 2.6).

Forms:It notes, "Internal benchmarking uses internal data for improvement, while competitive benchmarking focuses on rivals to gain a market edge" (CIPS L5M4 Study Guide, Chapter 2, Section 2.6). Both are vital for supply chain and financial optimization. References: CIPS L5M4 Study Guide, Chapter 2: Supply Chain Performance Management.

Describe 5 parts of the analysis model, first put forward by Porter, in which an organisation can assess the competitive marketplace (25 marks)

See the answer in Explanation below:

The analysis model referred to in the question is Porter’s Five Forces, a framework developed by Michael Porter to assess the competitive environment of an industry and understand the forces that influence an organization’s ability to compete effectively. In the context of the CIPS L5M4 Advanced Contract and Financial Management study guide, Porter’s Five Forces is a strategic tool used to analyze the marketplace to inform procurement decisions, supplier selection, and contract strategies, ensuring financial and operational efficiency. Below are the five parts of the model, explained in detail:

Threat of New Entrants:

Description: This force examines how easy or difficult it is for new competitors to enter the market. Barriers to entry (e.g., high capital requirements, brand loyalty, regulatory restrictions) determine the threat level.

Impact: High barriers protect existing players, while low barriers increase competition, potentially driving down prices and margins.

Example: In the pharmaceutical industry, high R&D costs and strict regulations deter new entrants, reducing the threat.

Bargaining Power of Suppliers:

Description: This force assesses the influence suppliers have over the industry, based on their number, uniqueness of offerings, and switching costs for buyers.

Impact: Powerful suppliers can increase prices or reduce quality, squeezing buyer profitability.

Example: In the automotive industry, a limited number of specialized steel suppliers may have high bargaining power, impacting car manufacturers’ costs.

Bargaining Power of Buyers:

Description: This force evaluates the influence buyers (customers) have on the industry, determined by their number, purchase volume, and ability to switch to alternatives.

Impact: Strong buyer power can force price reductions or demand higher quality, reducing profitability.

Example: In retail, large buyers like supermarkets can negotiate lower prices from suppliers due to their high purchase volumes.

Threat of Substitute Products or Services:

Description: This force analyzes the likelihood of customers switching to alternative products or services that meet the same need, based on price, performance, or availability.

Impact: A high threat of substitutes limits pricing power and profitability.

Example: In the beverage industry, the rise of plant-based milk (e.g., almond milk) poses a substitute threat to traditional dairy milk.

Competitive Rivalry within the Industry:

Description: This force examines the intensity of competition among existing firms, influenced by the number of competitors, market growth, and product differentiation.

Impact: High rivalry leads to price wars, increased marketing costs, or innovation pressures, reducing profitability.

Example: In the smartphone industry, intense rivalry between Apple and Samsung drives innovation but also squeezes margins through competitive pricing.

Exact Extract Explanation:

The CIPS L5M4 Advanced Contract and Financial Management study guide explicitly references Porter’s Five Forces as a tool for "analyzing the competitive environment" to inform procurement and contract strategies. It is presented in the context of market analysis, helping organizations understand external pressures that impact supplier relationships, pricing, and financial outcomes. The guide emphasizes its relevance in strategic sourcing (as in Question 11) and risk management, ensuring buyers can negotiate better contracts and achieve value for money.

Detailed Explanation of Each Force:

Threat of New Entrants:

The guide notes that "barriers to entry influence market dynamics." For procurement, a low threat (e.g., due to high entry costs) means fewer suppliers, potentially increasing supplier power and costs. A buyer might use this insight to secure long-term contracts with existing suppliers to lock in favorable terms.

Bargaining Power of Suppliers:

Chapter 2 highlights that "supplier power affects cost structures." In L5M4, this is critical for financial management—high supplier power (e.g., few suppliers of a rare material) can inflate costs, requiring buyers to diversify their supply base or negotiate harder.

Bargaining Power of Buyers:

The guide explains that "buyer power impacts pricing and margins." For a manufacturer like XYZ Ltd (Question 7), strong buyer power from large clients might force them to source cheaper raw materials, affecting supplier selection.

Threat of Substitute Products or Services:

L5M4’s risk management section notes that "substitutes can disrupt supply chains." A high threat (e.g., synthetic alternatives to natural materials) might push a buyer to collaborate with suppliers on innovation to stay competitive.

Competitive Rivalry within the Industry:

The guide states that "rivalry drives market behavior." High competition might lead to price wars, prompting buyers to seek cost efficiencies through strategic sourcing or supplier development (Questions 3 and 11).

Application in Contract Management:

Porter’s Five Forces helps buyers assess the marketplace before entering contracts. For example, if supplier power is high (few suppliers), a buyer might negotiate longer-term contracts to secure supply. If rivalry is intense, they might prioritize suppliers offering innovation to differentiate their products.

Financially, understanding these forces ensures cost control—e.g., mitigatingsupplier power reduces cost inflation, aligning with L5M4’s focus on value for money.

Practical Example for XYZ Ltd (Question 7):

Threat of New Entrants: Low, due to high setup costs for raw material production, giving XYZ Ltd fewer supplier options.

Supplier Power: High, if raw materials are scarce, requiring XYZ Ltd to build strong supplier relationships.

Buyer Power: Moderate, as XYZ Ltd’s clients may have alternatives, pushing for competitive pricing.

Substitutes: Low, if raw materials are specialized, but XYZ Ltd should monitor emerging alternatives.

Rivalry: High, in manufacturing, so XYZ Ltd must source efficiently to maintain margins.

This analysis informs XYZ Ltd’s supplier selection and contract terms, ensuring financial and operational resilience.

Broader Implications:

The guide advises using Porter’s Five Forces alongside other tools (e.g., SWOT analysis) for a comprehensive market view. It also stresses that these forces are dynamic—e.g., new regulations might lower entry barriers, increasing competition over time.

In financial management, the model helps buyers anticipate cost pressures (e.g., from supplier power) and negotiate contracts that mitigate risks, ensuring long-term profitability.

What is the difference between competitive and non-competitive sourcing? (12 marks)

In which circumstances may a non-competitive sourcing approach be more appropriate? (13 marks)

See the answer in Explanation below:

Part 1: What is the difference between competitive and non-competitive sourcing? (12 marks)

Competitive and non-competitive sourcing are two distinct approaches to selecting suppliers for procurement, each with different processes and implications. In the context of the CIPS L5M4 Advanced Contract and Financial Management study guide, these methods impact cost, supplier relationships, and contract outcomes. Below is a step-by-step comparison:

Definition and Process:

Competitive Sourcing: Involves inviting multiple suppliers to bid for a contract through a formal process (e.g., tendering, RFQs). Suppliers compete on price, quality, and other criteria.

Example: Issuing a tender for raw materials and selecting the supplier with the best offer.

Non-Competitive Sourcing: Involves selecting a supplier without a competitive bidding process, often through direct negotiation or sole sourcing.

Example: Directly negotiating with a single supplier for a specialized component.

Key Differences:

Competition: Competitive sourcing drives competition among suppliers, while non-competitive sourcing avoids it, focusing on a single supplier.

Transparency: Competitive sourcing is more transparent, with clear criteria for selection, whereas non-competitive sourcing may lack visibility and increase the risk of bias.

Cost Focus: Competitive sourcing often secures lower prices through bidding, while non-competitive sourcing prioritizes relationship or necessity over cost.

Time and Effort: Competitive sourcing requires more time and resources (e.g., tender management), while non-competitive sourcing is quicker but may miss cost-saving opportunities.

Part 2: In which circumstances may a non-competitive sourcing approach be more appropriate? (13 marks)

Non-competitive sourcing can be more suitable in specific situations where competition is impractical or less beneficial. Below are key circumstances:

Unique or Specialized Requirements:

When a product or service is highly specialized and only one supplier can provide it, non-competitive sourcing is necessary.

Example: Sourcing a patented technology available from only one supplier.

Urgency and Time Constraints:

In emergencies or when time is critical, competitive sourcing’s lengthy process may cause delays, making non-competitive sourcing faster.

Example: Sourcing materials urgently after a supply chain disruption (e.g., a natural disaster).

Existing Strategic Relationships:

When a strong, trusted relationship with a supplier exists, non-competitive sourcing leverages this partnership for better collaboration and reliability.

Example: Continuing with a supplier who has consistently delivered high-quality materials.

Low Value or Low Risk Purchases:

For small, low-risk purchases, the cost of a competitive process may outweigh the benefits, making non-competitive sourcing more efficient.

Example: Sourcing office supplies worth £500, where tendering costs exceed potential savings.

Exact Extract Explanation:

Part 1: Difference Between Competitive and Non-Competitive Sourcing

The CIPS L5M4 Advanced Contract and Financial Management study guide addresses sourcing approaches in the context of strategic procurement, emphasizing their impact on cost and supplier relationships. It describes competitive sourcing as "a process where multiple suppliers are invited to bid," promoting transparency and cost efficiency, while non-competitive sourcing is "direct engagement with a single supplier," often used for speed or necessity.

Detailed Comparison:

The guide highlights that competitive sourcing aligns with "value for money" by leveraging market competition to secure better prices and terms. For example, a tender process might reduce costs by 10% through supplier bids.

Non-competitive sourcing, however, is noted as "less transparent" but "faster," suitable when competition isn’t feasible. It may lead to higher costs due to lack of price comparison but can foster stronger supplier relationships.

L5M4 stresses that competitive sourcing requires "formal processes" (e.g., RFQs, tenders), increasing administrative effort, while non-competitive sourcing simplifies procurement but risks bias or favoritism.

Part 2: Circumstances for Non-Competitive Sourcing

The study guide identifies scenarios where non-competitive sourcing is preferable, particularly when "speed, uniqueness, or strategic relationships" outweigh the benefits of competition.

Unique Requirements: The guide notes that "sole sourcing is common for specialized goods," as competition is not viable when only one supplier exists.

Urgency: L5M4’s risk management section highlights that "time-sensitive situations" (e.g., emergencies) justify non-competitive sourcing to avoid delays.

Strategic Relationships: The guide emphasizes that "long-term partnerships" can justify non-competitive sourcing, as trust and collaboration may deliver greater value than cost savings.

Low Value Purchases: Chapter 2 suggests that for "low-value transactions," competitive sourcing may not be cost-effective, supporting non-competitive approaches.

Practical Application: For XYZ Ltd (Question 7), non-competitive sourcing might be appropriate if they need a unique alloy only one supplier provides or if a sudden production spike requires immediate materials.

Explain three different types of financial data you could collect on a supplier and what this data would tell you (25 marks)

See the answer in Explanation below:

Collecting financial data on a supplier is a critical step in supplier evaluation, ensuring they are financially stable and capable of fulfilling contractual obligations. In the context of the CIPS L5M4 Advanced Contract and Financial Management study guide, analyzing financial data helps mitigate risks, supports strategic sourcing decisions, and ensures value for money in contracts. Below are three types of financial data, their purpose, and what they reveal about a supplier, explained in detail:

Profitability Ratios (e.g., Net Profit Margin):

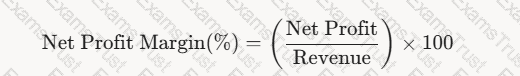

Description: Profitability ratios measure a supplier’s ability to generate profit from its operations. Net Profit Margin, for example, is calculated as:

A math equation with numbers and symbols

AI-generated content may be incorrect.

A math equation with numbers and symbols

AI-generated content may be incorrect.

This data is typically found in the supplier’s income statement.

What It Tells You:

Indicates the supplier’s financial health and efficiency in managing costs. A high margin (e.g., 15%) suggests strong profitability and resilience, while a low or negative margin (e.g., 2% or -5%) signals potential financial distress.

Helps assess if the supplier can sustain operations without passing excessive costs to the buyer.

Example: A supplier with a 10% net profit margin is likely stable, but a declining margin over years might indicate rising costs or inefficiencies, posing a risk to contract delivery.

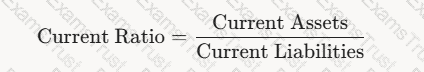

Liquidity Ratios (e.g., Current Ratio):

Description: Liquidity ratios assess a supplier’s ability to meet short-term obligations. The Current Ratio is calculated as:

A black text on a white background

AI-generated content may be incorrect.

A black text on a white background

AI-generated content may be incorrect.

This data is sourced from the supplier’s balance sheet.

What It Tells You:

Shows whether the supplier can pay its debts as they come due. A ratio above 1 (e.g., 1.5) indicates good liquidity, while a ratio below 1 (e.g., 0.8) suggests potential cash flow issues.

A low ratio may signal risk of delays or failure to deliver due to financial constraints.

Example: A supplier with a Current Ratio of 2.0 can comfortably cover short-term liabilities, reducing the risk of supply disruptions for the buyer.

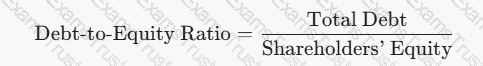

Debt-to-Equity Ratio:

Description: This ratio measures a supplier’s financial leverage by comparing its total debt to shareholders’ equity:

A math equation with black text

AI-generated content may be incorrect.

A math equation with black text

AI-generated content may be incorrect.

This data is also found in the balance sheet.

What It Tells You:

Indicates the supplier’s reliance on debt financing. A high ratio (e.g., 2.0) suggests heavy borrowing, increasing financial risk, while a low ratio (e.g., 0.5) indicates stability.

A high ratio may mean the supplier is vulnerable to interest rate hikes or economic downturns, risking insolvency.

Example: A supplier with a Debt-to-Equity Ratio of 0.3 is financially stable, while one with a ratio of 3.0 might struggle to meet obligations if market conditions worsen.

Exact Extract Explanation:

The CIPS L5M4 Advanced Contract and Financial Management study guide emphasizes the importance of financial due diligence in supplier selection and risk management, directly addressing the need to collect and analyze financial data. It highlights that "assessing a supplier’s financial stability is critical to ensuring contract performance and mitigating risks," particularly in strategic or long-term contracts. The guide specifically references financial ratios as tools to evaluate supplier health, aligning with the types of data above.

Detailed Explanation of Each Type of Data:

Profitability Ratios (e.g., Net Profit Margin):

The guide notes that profitability metrics like Net Profit Margin "provide insight into a supplier’s operational efficiency and financial sustainability." A supplier with consistent or growing margins is likely to maintain quality and delivery standards, supporting contract reliability.

Application: For XYZ Ltd (Question 7), a raw material supplier with a declining margin might cut corners on quality to save costs, risking production issues. L5M4 stresses that profitability data helps buyers predict long-term supplier viability, ensuring financial value.

Liquidity Ratios (e.g., Current Ratio):

Chapter 4 of the study guide highlights liquidity as a "key indicator of short-term financial health." A supplier with poor liquidity might delay deliveries or fail to fulfill orders, directly impacting the buyer’s operations and costs.

Practical Use: A Current Ratio below 1 might prompt XYZ Ltd to negotiate stricter payment terms or seek alternative suppliers, aligning with L5M4’s focus on risk mitigation. The guide advises using liquidity data to avoid over-reliance on financially weak suppliers.

Debt-to-Equity Ratio:

The guide identifies leverage ratios like Debt-to-Equity as measures of "financial risk exposure." A high ratio indicates potential instability, which could lead to supply chain disruptions if the supplier faces financial distress.

Relevance: For a manufacturer like XYZ Ltd, a supplier with a high Debt-to-Equity Ratio might be a risk during economic downturns, as they may struggle to access credit for production. The guide recommends using this data to assess long-term partnership potential, a key financial management principle.

Broader Implications:

The guide advises combining these financial metrics for a comprehensive view. For example, a supplier with high profitability but poor liquidity might be profitable but unable to meet short-term obligations, posing a contract risk.

Financial data should be tracked over time (e.g., 3-5 years) to identify trends—e.g., a rising Debt-to-Equity Ratio might signal increasing risk, even if current figures seem acceptable.

In L5M4’s financial management context, this data ensures cost control by avoiding suppliers likely to fail, which could lead to costly delays or the need to source alternatives at higher prices.

Practical Application for XYZ Ltd:

Profitability: A supplier with a 12% Net Profit Margin indicates stability, but XYZ Ltd should monitor for declines.

Liquidity: A Current Ratio of 1.8 suggests the supplier can meet obligations, reducing delivery risks.

Debt-to-Equity: A ratio of 0.4 shows low leverage, making the supplier a safer long-term partner.

Together, these metrics help XYZ Ltd select a financially sound supplier, ensuring contract performance and financial efficiency.

Copyright © 2014-2026 Examstrust. All Rights Reserved